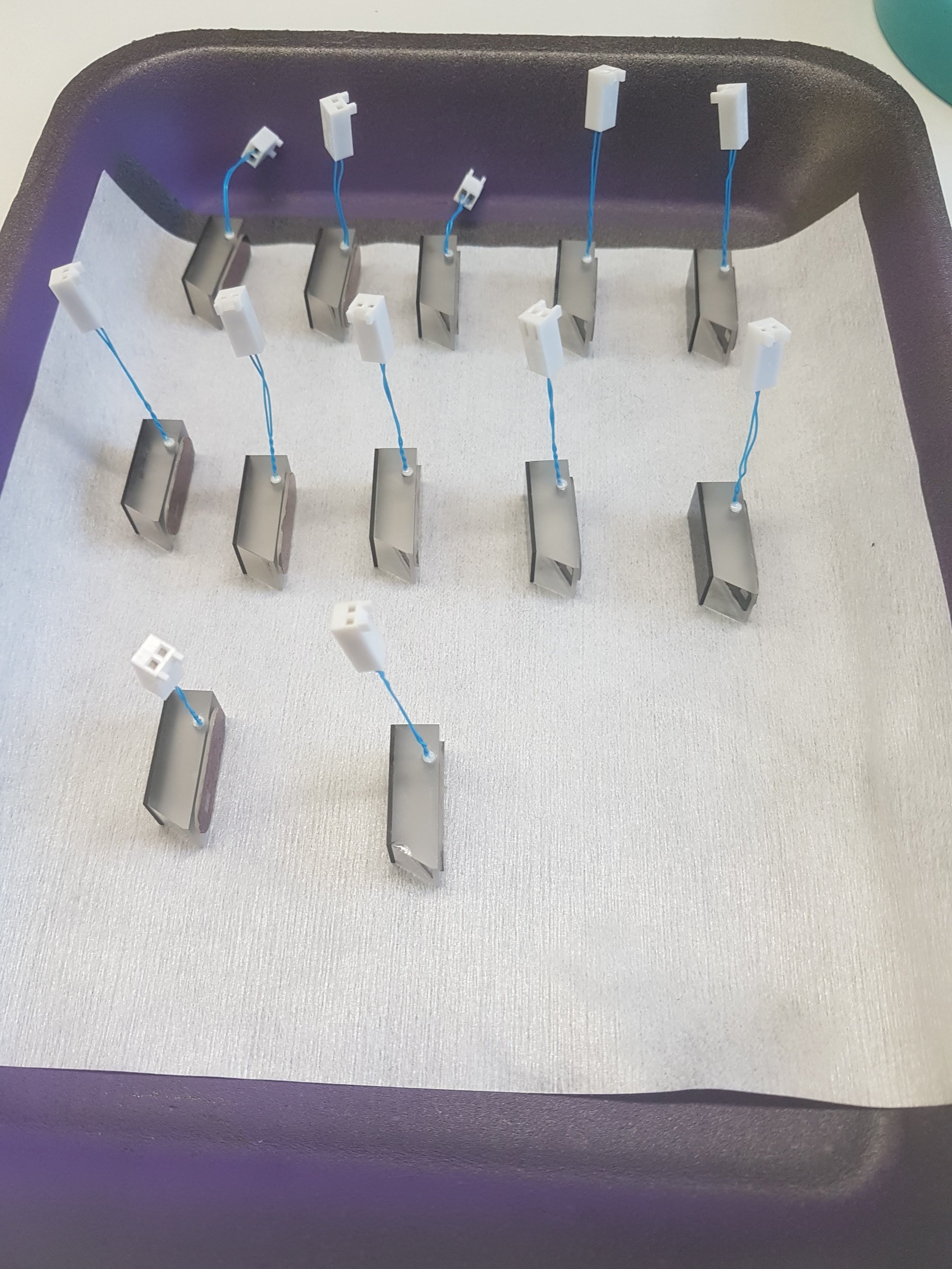

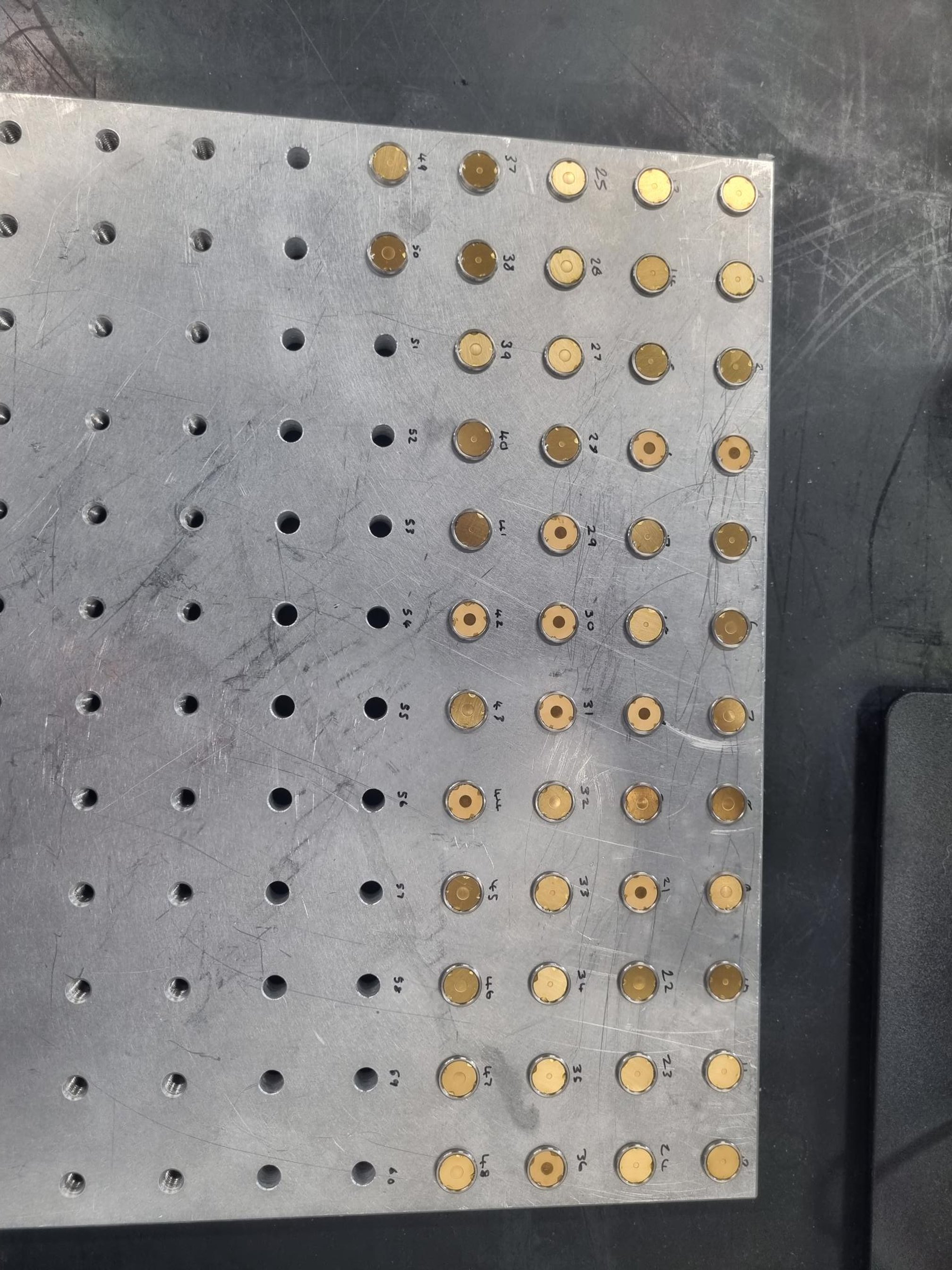

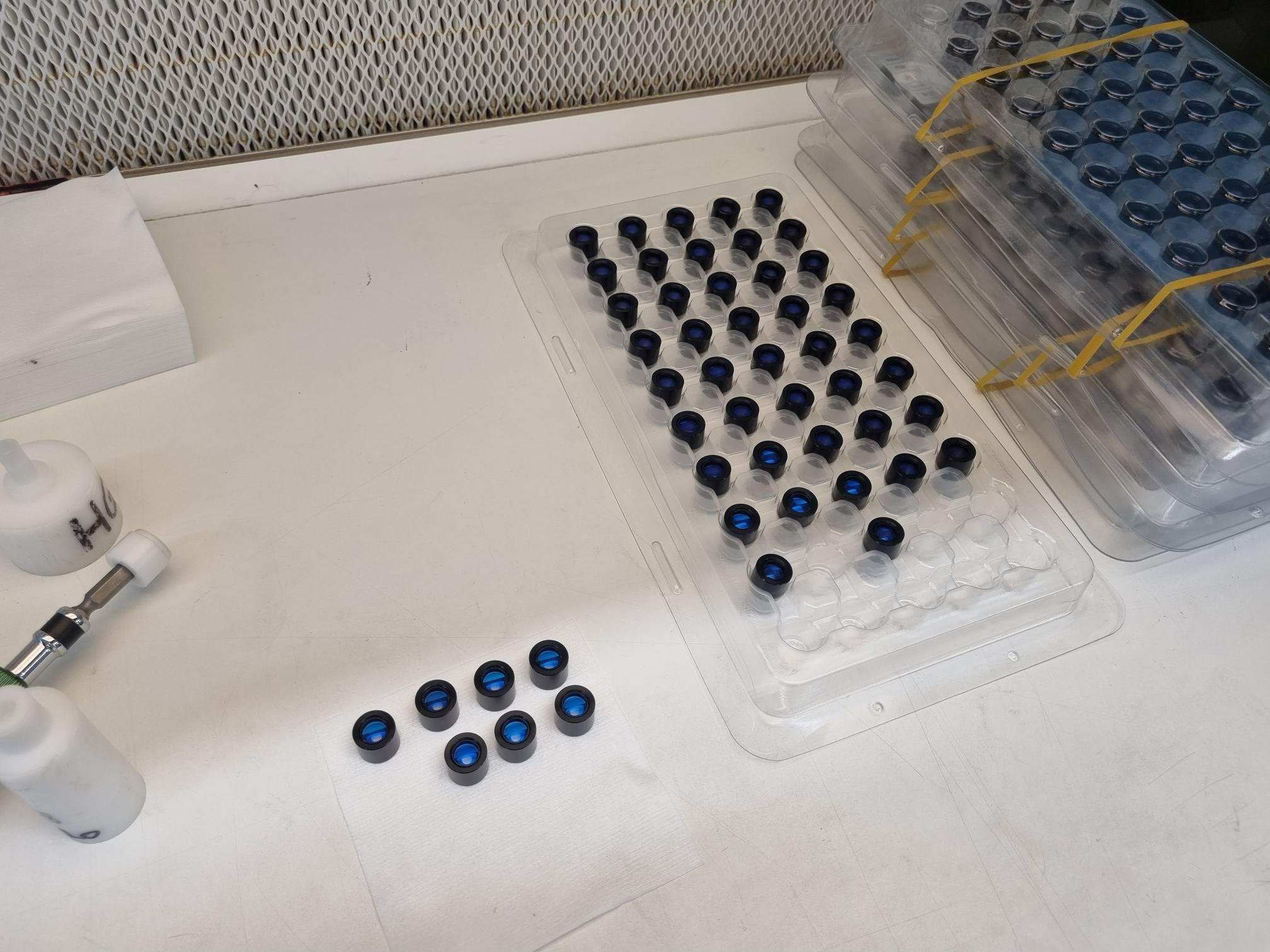

Optical assemblies

Here at Comar one of our specialities is optical assemblies. We have years of experience in assembling optical and mechanical parts into many types of assembly, from gobo projectors (structured light assemblies) to LED illuminators and laser modules. Typical volumes are anywhere from tens to tens of thousands per year.

Production line issues?

Do you have issues on your production line with handling and assembling optics? Optics are delicate and sensitive to handle, and can be very difficult for workers to assemble and clean correctly. We can provide optical subassemblies clean and packed in your preferred batch sizes ready for your production line to slot straight into your instruments, reducing part count, handling damage and cleaning time.

We can also provide parts ready kitted for your store teams.

Manufacturing questions?

Struggling to work out the best way to assemble your components? We have production engineers on hand with years of experience who are happy to help. We can discuss and advise on manufacturing methods and typical challenges for example:

Adhesive and bonding methods including dispenser types

Optical and mechanical tolerancing

Mounting methods

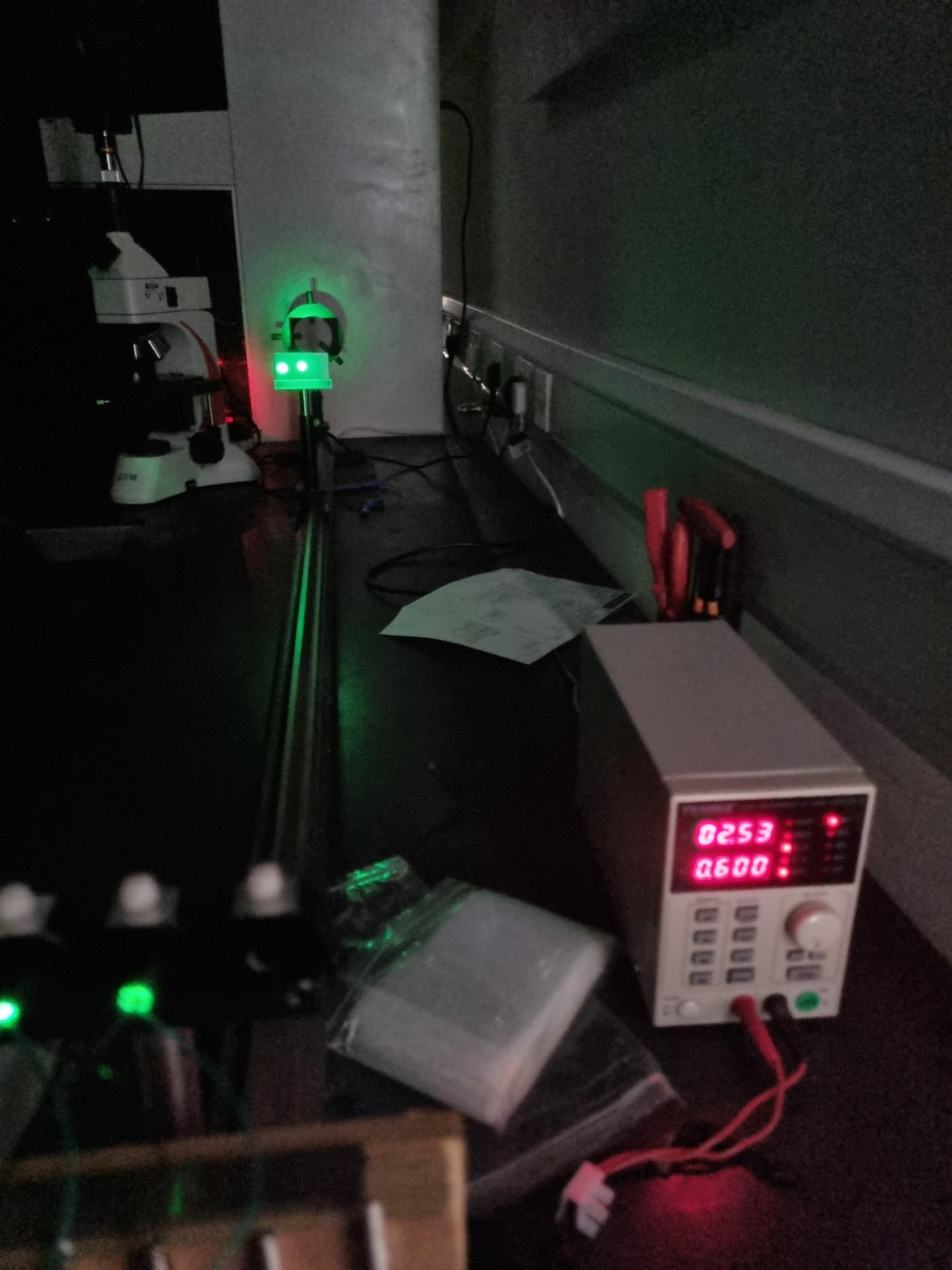

Complex optical or optomechanical specifications?

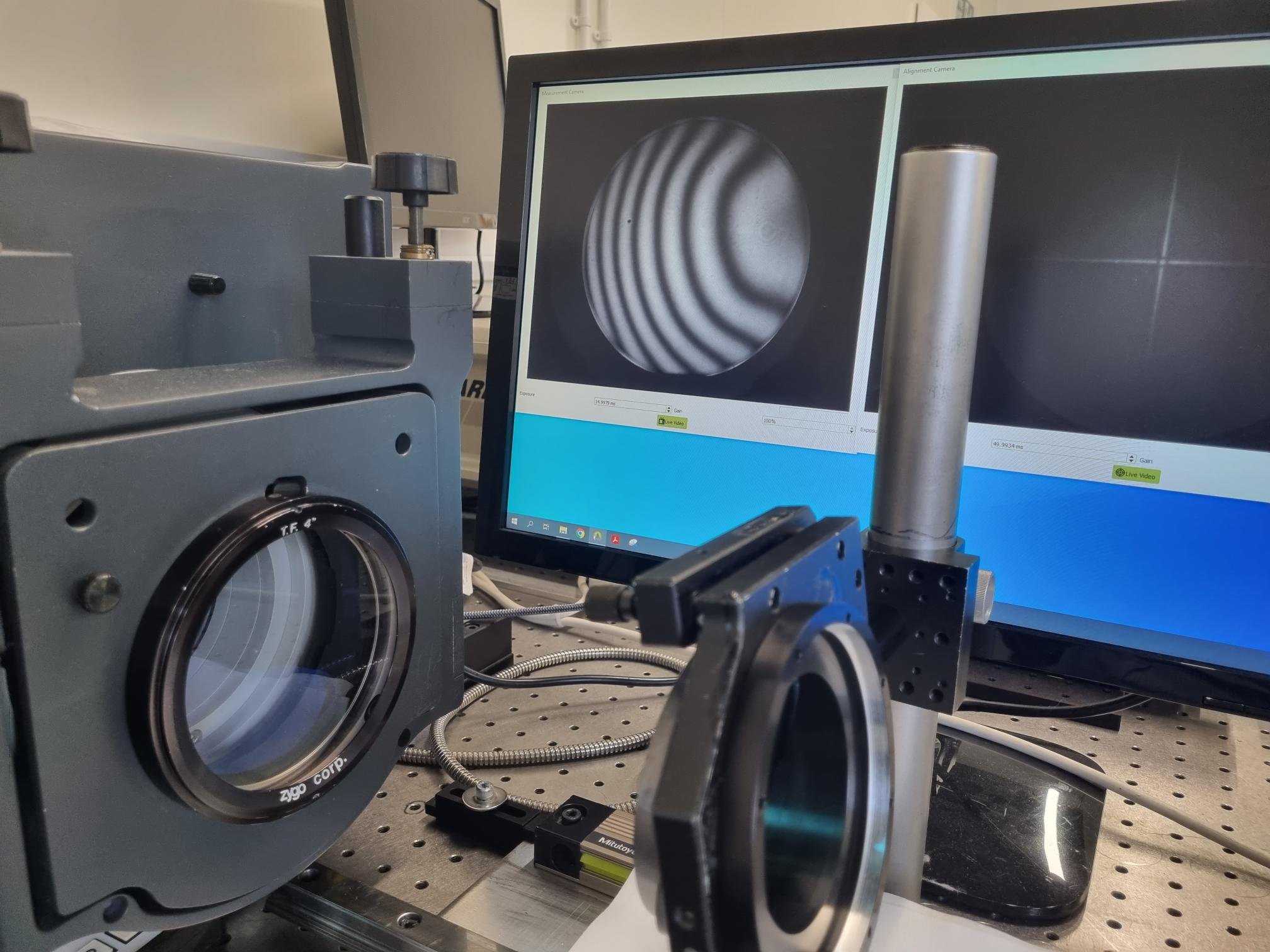

Due to our significant range of optical testing equipment, we can complete optical testing on completed assemblies if required, to ensure they meet your optical specifications. Typical post-assembly testing includes:

Flatness

Transmitted wavefront deviation (TWE)

Alignment

Centration

Projection testing

MTF testing

Boresight alignment

Focusing of collimators